Instant, permanent repairs on the go!

There are all sorts of adhesive tapes and glues out there in the world that purport to be the panacea for all your everyday woes and mishaps.

But none compare to the versatility, the effectiveness, the durability or the efficacity of Tear-Aid® when it comes to fixing your stuff quickly, simply, easily – and permanently.

Two flavours, a ton of varieties

There are two types of Tear-Aid® tape, one of which is most likely perfectly adapted to the type of repair job you need to carry out.

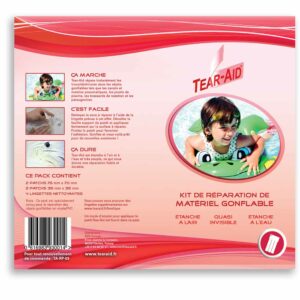

If you’re needing to repair your bouncy castle, your garden pool or your PVC fishing gear, then you’ll need to get your hands on our Tear-Aid® Type B tape.

If, however, you’ve a cotton canvas, poly-cotton or polyester tent, a poly(thene) tunnel, a technical, breathable or down-filled jacket, a nylon rucksack, or maybe even a wetsuit or a bicycle inner tube to repair, then you’ll need our Type A.

Choosing the right Type

Oh, and if you don’t know what sort of material you need to fix, are unsure of the material or its composition, or even we cannot tell you over the phone despite our vast experience, then, well, we also offer a test kit that we sell at virtually cost, so you can reassure yourself about what you need – Type A or Type B – before committing.

Tear-Aid® Type A

With the exception of PVC and vinyl products, Tear-Aid® Type A fixes just about everything – and it does so extremely quickly.

To find out more about Type A, just click on the link below.

Tear-Aid® Type B

Tear-Aid® Type B is specially formulated to form a permanent bond on vinyls and PVC materials and products.

It is ideal for repairing anything from pool and pond liners to car seats, dry bags and ground sheets.

Cut, Peel, Stick!

Fixing stuff with Tear-Aid® is – almost – child’s play.

But all the same, some very simple rules need to be observed if you are going to achieve a neat, clean, barely visible and strong repair.

But don’t worry, every pack we sell comes complete with an extremely comprehensive instruction leaflet that outlines not only how to carry out the perfect repair, but also how to handle the stuff that most tapes cannot cope with, including instant underwater repairs and corrugated aluminium ducting repairs!

Sounds simple? You'd be right!

What we can tell you here, before you commit to buying our product, is that everything relies on the condition and the preparation of the surface or material you need to repair, prior to sticking your Tear-Aid® patch into place.

Because if you skimp on the cleaning and degreasing, or if your item is just – well – totally beyond repair, your patch will just simply… come away, leaving you to start over.

Or maybe it’s just time to invest in new gear?

Available in transparent, for the most discreet of repairs!

Save money

Fixing your stuff means keeping more of your money in your pocket – now that’s got to be a win-win!

Total Genius

Just because it looks like any other transparent tape, doesn’t mean it is. Tear-Aid® is simply pure technical excellence.

Ultra-fast acting

Tear-Aid® won’t keep you hanging around. Seconds to prepare and apply, and minutes to cure – job done!

Who we supply

We have been selling Tear-Aid® to the general public & retailers for many years.

But did you know we also supply a very wide range of professionals?

The military, fire departments, schools, colleges & universities, veterinary, health, dental, paramedical and medical practices, bouyancy aid & lifeboat equipment manufacturers, hospital & paramedical equipment providers & end-users, gymnasia, soft play area suppliers & operators, camp sites, leisure & theme parks, extreme sports professionals, upholstery & restoration companies, second life associations, outdoor pursuits equipment & gear suppliers, DIY stores, cobblers & shoe repair outlets, etc.

And with every day that passes, the list just gets longer – evidence that more and more people are coming to understand the importance of making things last longer.

Why Tear-Aid®?

Repair, reuse, repurpose

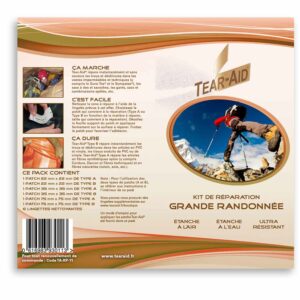

You might find yourself in the middle of nowhere, whereby if you don’t repair your gear straight away, either it will get worse or fail completely. Whether we’re talking about your waterproofs, your sleeping bag, your tent outer, your drinks container or your rucksack, if you don’t fix it, at the very least you’re in for a miserable time – and the very worst might just be you putting your life on the line.

I’d never get on my bike without making sure I have a couple of Tear-Aid® patches and a bike pump on me, in case I get a puncture. A kit weighs next-to-nothing, takes up virtually no space at all, yet it could save me hours of pushing my bike back home!

Similarly, before you decide to fill up your garden swimming pool, make sure you’ve some Tear-Aid® Type B to hand in case it has developed a leak since last year. Waiting for the postman to deliver your pack AFTER discovering the leak could cost a lot in lost water.

Reduce waste and carbon emissions

Fixing stuff is always satisfying. You save loads of money, extend your gear’s life, and set an example to others who hopefully will do the same.

After all, nothing’s cheap these days, so if you can make your stuff last, then go for it! (And save up for some quality things down the line when you finally have to take your old stuff to the recycling depot).

If you’re an avid outdoor enthusiast, preferring the technical properties of synthetic fibres over natural fibres, you already know too well just how vulnerable these expensive lightweight fabrics are to rubbing, thorns, ripping, etc. Patching them up before a hole becomes a tear becomes an unintended ventilation opening just seems to be a no-brainer, especially as you can do it on the fly!

Every time you repair an item, that’s less carbon you’re throwing into the atmosphere and less stuff ending up in landfill to rot (or break down into nanoplastic particles as the case may be…).

Help nature, help the planet

Prolonging the amount of time before your things finally pop their mortal coil and make their way to the great tip in the sky (or rather the incinerator or the landfill site or, worse, the ocean or the ice caps – we exaggerate not…) has got to be in the interests of every living creature on this planet.

Global supply chains and fast fashion give the impression that we can all live as if there was no tomorrow, that everything will all work out in the end.

Well, here’s the surprise!

At the rate we are going, and the manner in which we consume the earth’s resources and energy – there won’t be anything left to consume soon, and we’ll all be more concerned with how to survive Mother Earth’s wrath!

If your stuff breaks, tears, punctures or in any other way lets you down, then repair it. If it is beyond repair, dispose of it responsibly, preferably by recycling it, then buy responsibly.

What our clients say...

“Réparation de ma tente au top! Super produit très facile à utiliser . Je le recommande et le rachèterai si besoin.”

MélissaOn Tear-Aid Type A

“ce ... kit à sauvé ma veste technique de Trail en polyuréthane que j'avais accroché sur une branche de sapin à une manche sur 8 bon cm , la réparation ne se voit pas et est très solide, la veste est comme neuve.”

Jean-PierreTear-Aid Type A

Type A versus Type B

Type A

Tear-Aid® Type A

Tear-Aid® Type A fixes just about any sort of fabric or material except those made of PVC or vinyl, or any products with a PVC or vinyl coating such as sou’wester coats used in the sea fishing industry, where the repair needs to be carried out on the coating side.

The Tear-Aid® patch is semi-transparent (or semi-opaque), meaning that it will blend in well with any surface, whether it be black, white, coloured or even transparent.

If the surface is printed, such as with a logo, this will still be visible after the repair.

If the repair needs to be completely transparent, then a heat gun (or failing that a powerful hair-dryer) should be used to carefully warm the patch once it has been applied. Maintain the heat until the patch becomes fully transparent. Do not overheat the patch as this will cause it to wrinkle and come away, meaning you will have to start over with a new patch.

Instant adhesion

Our Tear-Aid® Type A patches rapidly form an extremely strong bond with whatever material you wish to use them on.

In fact, the patch will be 90% bonded within just 10 minutes of its application – and 100% bonded within the hour. Heating the patch, as described above, also reduces bonding time.

For instance, the time it takes to repair a bicycle inner tube with a Tear-Aid® patch (no glue needed), refit the inner tube and blow up the tyre to its usual pressure, is normally sufficient for the patch to bond to the rubber or latex inner tube and let you continue your journey!

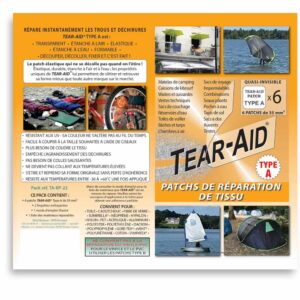

What does Type A work on?

- Canvas

- Nylon

- Rubber

- Neoprene

- Polyethylene (PE)

- Hypalon

- Sunbrella®

- Pertex®

- Acrylic

- Dacron

- Fibreglass

- Aluminium

- Polypropylene (PP)

- PET

- Polyester

- Polyurethane (PU)

- Cotton

- Polycotton

- Leather (non-oiled)

- Elastane (aka Spandex or Lycra)

- Breathable fabrics including:

- Gore-Tex®

- eVent®

- Sympatex®

Technical

fabrics

We have tested Type A with all of the fabrics we mention and have listed here for your information. It is important to note that mentioning these fabrics does not in any way suggest the owners of the brands and trademarks mentioned (and which we hereby acknowledge) have endorsed the use of Tear-Aid® with their products.

The same goes for products that feature in photos we have taken and used on this website.

Finally, we welcome your feedback on new materials you have tested, so we can add to this list and thus help others.

What doesn't stick?

However, Tear-Aid® will not stick to everything, so you may need to test your material beforehand. Some more obvious examples are felt-like materials, wool, waxed cotton jackets and teflon.

Applying patches to the silicone side of fabrics that are silicone-coated to make them waterproof, is also a problem as the patch will come away, taking the silicone with it.

If in doubt, test the material either by purchasing a Tear-Aid® test kit (available here) or by cutting out a small piece of patch you already have, and applying it to an area that will not be readily noticable, making sure of course that you observe the application instructions provided.

If after an hour the patch can be readily removed, or it bonds only partially, then you will need to find an alternative solution.

So why choose Tear-Aid®?

- UV-resistant, the patch will not discolour or become brittle over time when exposed to sunlight.

- Easy to cut to shape and size using scissors.

- No sewing necessary.

- Stops tears from running or getting worse.

- No messy liquid glues to apply.

- Will not turn gummy at high temperatures.

- Stretches and springs back to shape without losing any grip.

- Once cured, will continue to function normally between -30 and +60 °C.

Type B

Tear-Aid® Type B

Tear-Aid® Type B is specially formulated to form a permanent bond with vinyl and PVC materials and products.

The new, unique adhesive is specially formulated to counter the oils present in PVC and vinyls which prevent other glues and self-adhesive patches from forming permanent bonds.

Our patch+adhesive combination also ensures the end result is totally flexible, whereas other glue-based products either harden and become brittle, discolour over time, become sticky when exposed to the sun, or simply peel off.

Permanent fix

Immediately you apply a Type B patch, it is 50% bonded, which is enough to make sure it stays put, but not enough to prevent you from repositioning the patch if necessary.

The patch should then be left for 24 hours for the bond to reach 100% adhesion. After this time, your repair is not only permanent, it will most likely outlast the material it is stuck to.

And just like with our Type A patch, after applying the patch you can carefully warm it using a heat gun (preferred) or powerful hair dryer which will have the dual benefit of making the patch totally transparent and reduce bonding time down from 24 hours to a few minutes.

Underwater repairs

If you own an above-ground or PVC-lined swimming pool, make sure you have your Tear-Aid® Type B Underwater Repair Pack to hand BEFORE you begin filling it with water.

Holes in pool liners are notoriously difficult to detect at the best of times, and many an owner has watched their pool drain while awaiting the arrival of their repair kit in the post.

The Underwater Repair Kit works on both dry and submerged PVC liners – the latter are harder to clean, for sure, but our kit includes comprehensive instructions to ensure a successful repair. All you need to do is follow the enclosed instructions to the letter.

Immediately you apply a Type B patch, it is 50% bonded, which is enough to make sure it stays put, but not enough to prevent you from repositioning the patch if necessary.

The patch should then be left for 24 hours for the bond to reach 100% adhesion. After this time, your repair is not only permanent, it will most likely outlast the material it is stuck to.

And just like with our Type A patch, after applying the patch you can carefully warm it using a heat gun (preferred) or powerful hair dryer which will have the dual benefit of making the patch totally transparent and reduce bonding time down from 24 hours to a few minutes.

Old PVC and vinyl

A word of warning about vinyls and PVC – they dry out, become brittle, and cannot be repaired with Tear-Aid® Type B!

If your item shows signs of cracking, has lost its shine, or is very faded, the chances are the Type B repair patches will NOT work. The adhesive on our patches chemically reacts with the vinyl’s oils, so if the oils have “dried up” (for want of a better term), YOU WOULD BE BETTER OFF making your repair with a Type A patch.

That said, your item is also clearly close to the end of its useful life, and it might be better just to replace it. Your choice.

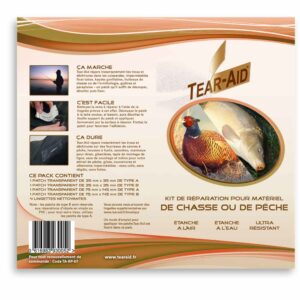

Repairables

- Boat towables

- Tarpaulins

- Vinyl car seats

- Dry bags

- Caving rope bags

- Cushions

- RV awnings

- Air mattresses

- PVC roll-top paniers

- ATV seats

- PVC roll-top rucksacks

- Pool liners

- Boat & yacht seat cushions

- Vinyl tents & groundsheets

- Inflatables

The above list is not exhaustive, and if you have anything you’d like to add, then please let us know using the contact form which is available by clicking here.

Main Features

- UV-resistant, the patch will not discolour or become brittle over time when exposed to sunlight.

- Easy to cut to shape and size using scissors.

- No sewing necessary.

- Stops tears from running or getting worse.

- No messy liquid glues to apply.

- Will not turn gummy at high temperatures.

- Stretches and springs back to shape without losing any grip.

- Once cured, will continue to function normally between -30 and +90 °C.

Some useful stuff...

Product formats

In case we’ve not said it enough, Tear-Aid® is available in two types:

- Type A is designed to repair most synthetic and natural fabrics with the exception of vinyls and PVC;

- Type B is designed to repair PVC and vinyls.

Both types are available in lengths of up to 30 ft (approximately 9 metres) in the following widths:

- 1 1/4″ (32 mm approx.)

- 3″ (75 mm approx.)

- 6″ (150 mm approx.)

In addition, we also supply patches:

- 7/8″ x 7/8″ (22 mm x 22 mm approx.)

- 1 3/8″ x 1 3/8″ (35 mm x 35 mm approx.)

Finally, we offer a range of Activity packs designed specifically to meet a range of needs and activities.

General specifications

Tear-Aid® is a durable, elastic, airtight, watertight, puncture-resistant industrial-strength patch that protects against abrasion, moisture, saltwater, UV sunlight and extreme temperatures.

Once applied, Tear-Aid® can resist ambient temperatures of between:

- -30 °C and +60 °C in the case of Type A, and

- -30 °C and +90 °C in the case of Type B.

Under normal conditions, Type A achieves 90% of its full bonding strength within 10 minutes of it being applied, and 100% within one hour. It is NOT repositionnable once it has been applied.

On the other hand, Type B takes longer to reach its full bonding strength (50% immediately it is applied, 100% 24 hours later). It is repositionnable for a short period of time, and curing can be accelerated by carefully heating the patch.

Handle with care and avoid touching the glued surface.

For more information

You can obtain further information on Tear-Aid® by visiting our dedicated websites:

- tearaid.fr (France & French Territories, Canada)

- tear-aid.uk.com (UK and Northern Ireland)